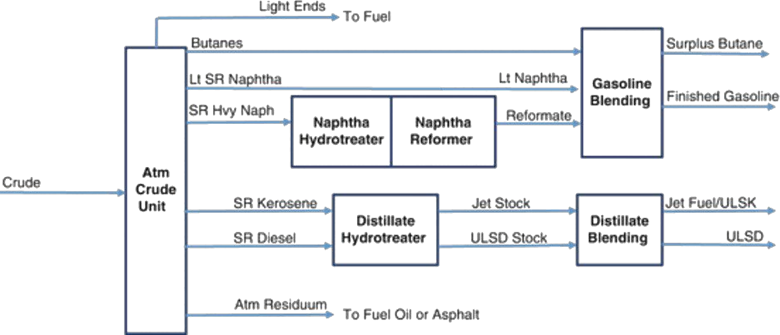

Hydroskimming Refinery

HYDROSKIMMING REFINERY

Process flow

Different Capacity

A Hydoskimming refinery uses fractional and reactor technology which produces PMS, Jet A fuel, Diesel, HPFO/LPFO

|

S/N |

TYPE |

CAPACITY |

LAND |

POWER |

|

1 |

H100 |

1,000BPD |

10 Hectares |

2MW |

|

2 |

H200 |

2,000BPD |

15 Hectares |

3.5MW |

|

3 |

H500 |

5,000BPD |

25 Hectares |

5MW |

More information please contact: office@afcomoilandgas.com

Know How and Technology of Hydroskimming Refinery

The modular oil refinery’s core technology is based on the up to date internal technology from Afcom Oil and Gas. As we know internal’s efficiency influence the unit size and energy consumption. We are the member of FRI(which is non-profit organization founded by most esteemed chemical company like Exxon Mobil, Shell, Dow, etc. And the most authoritative research group in internal field). Our newest patent packing Winpak is widely used in the oil and gas field and win very good reputation from our customers.

- Jet guided trapezoidal floating valve(SGTV)

SGTV is high-performance float valve tray, researched and developed by Tianjin University, on the basis of absorbing the application of bar float valve, fixed tongue and guided sieve tray experience from domestic and overseas. (Patent no. 00204491.9). The valve plate shape is divided into two kinds of models A and B, absorbed the characteristics of the V type grid, changing the rectangular valve plate to trapezoid, making propelling action strengthened. Especially the B type float valve, not only opens holes on the side of the type A float valve, but also adds a hole in front of the body, plays a guide role in real, at the same time, strengthens the propelling action. On the structure, using gas circulation area adjustable floating valve structure overcomes the small operation flexibility of V- grid. Experimental research and practical application show that the SGTV greatly improves the performance of the plate.

- Winpak packing

Through continuous improvement of traditional packing, Afcom Oil and Gas has a series of new high efficiency structured packings with independent intellectual property rights, the main product is Winpak series packing. Compared to the conventional plate corrugated packing with same surface area, our packing’s plate efficiency improves more than 25-50%, while pressure drop decreases. New packing has been applied in hundreds of towers in oil refining, petrochemical and other industries.